A pump is a device used to move fluids by mechanical action. Pumps can move liquids, gases, slurries, or granular solids, and are used in many different industries. Many types of pumps are available, each with its own advantages and disadvantages. Pumps are used to move fluids by either displacement or centrifugal force.

Displacement pumps use a piston, gear, or vane to move the fluid. Centrifugal pumps use an impeller to draw the fluid in and then spin it to create centrifugal force, which propels the fluid out. Pumps can be classified by their power source, operating principle, their application, or their geography. Electric pumps are the most common type, followed by hydraulic and pneumatic pumps.

Pumps are used in many different industries, including automotive, chemical, food and beverage, oil and gas, pharmaceutical, and power generation. In each industry, there are specific types of pumps that are designed for a particular application. Pumps are an essential part of many industrial and consumer products. They are used in everything from cappuccino machines to car washes, and dishwashers to water parks.

Pumps come in all shapes and sizes, and there is a pump for almost every application.

A pump is a machine that uses energy to move a fluid from one place to another. Pumps are used to move water, oil, and other liquids, as well as to move air and other gases. Pumps are used in many industries, including the food and beverage, pharmaceutical, oil and gas, and power generation industries.

What Are Pumps?

Pumps are devices that are used to move fluids or gases by mechanical or physical means. Pumps work by using one or more mechanical devices to create a pressure differential, which in turn moves the fluid or gas from one location to another. Pumps are used in a wide variety of applications, from moving water from one location to another to moving air in HVAC systems to moving chemicals and other fluids in industrial settings.

Pumps come in a wide variety of designs and can be powered by a variety of means, including electric motors, gasoline engines, or even hand cranks.

What Are The Different Types Of Pumps?

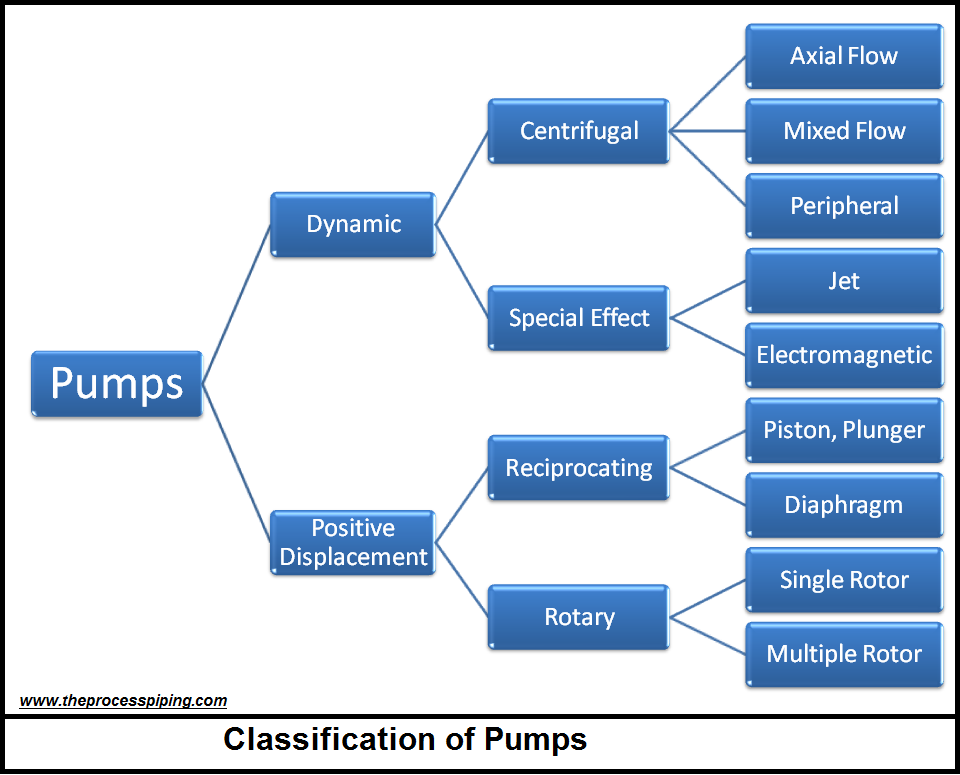

A pump is a device that moves fluids (liquids or gases), or sometimes slurries, by mechanical action. Pumps can be classified into three major groups according to the method they use to move the fluid: direct lift, displacement, and gravity pumps. Pumps operate by some mechanism (typically reciprocating or rotary) and consume energy to perform mechanical work moving the fluid. Pumps displacement pumps Directional control valves Flow control valves Force pumps Lift pumps Peristaltic pumps Positive displacement pumps Reciprocating pumps Rotary pumps direct lift pumps use a suction cup or similar mechanism to create a vacuum beneath the object to be lifted, and then atmospheric pressure lifts the object.

displacement pumps, such as piston pumps, diaphragm pumps, and gear pumps, use a rotating mechanism to move a sliding piston or vaned rotor to displace the fluid. centrifugal or radial flow pumps, use an impeller to draw fluid into a rotating shaft, then fling it outwards to the pump casing where it exits. Gravity pumps rely on a difference in elevation between the source of the fluid and the destination to provide the necessary head.

What Are The Different Applications Of Pumps?

Pumps are devices that are used to move fluids by mechanical means. Pumps are used in a variety of applications, including Moving water from a well or reservoirTransferring hot water from a boiler circulating water in a cooling system delivering oil or gas to a refinery or pipeline pumps come in a variety of designs, each suited for a specific application.

For instance, centrifugal pumps are well suited for moving large volumes of water, while reciprocating pumps are better suited for high-pressure applications, such as in a hydraulic system.

What Are The Main Components Of A Pump?

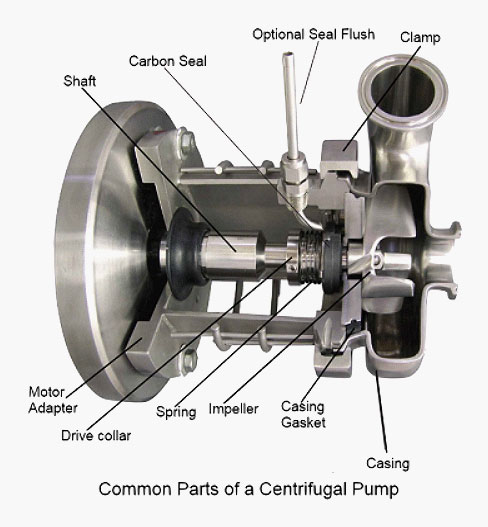

The three main components of a pump are the pump housing, impeller, and motor. The pump housing contains the fluid being pumped and directs it to the impeller. The impeller is a rotating device that creates a vacuum that pulls the fluid through the pump.

The motor provides the power to turn the impeller.

How Do Pumps Work?

The mechanism by which pumps work is fairly simple. They work by using a sealed chamber in which a piston is placed. This piston is connected to a handle, which when turned, creates a vacuum.

This vacuum pulls the water up the chamber and into the piston, which is then pushed out into the outlet pipe.

What Are The Main Types Of Fluids That Are Pumped?

There are many types of fluids that can be pumped, but the three most common are water, oil, and air. Each type of fluid has different characteristics that make it better suited for different applications. Water is the most common type of fluid that is pumped. It is relatively inexpensive and easy to obtain, and it has a very low viscosity, which means it is easy to pump.

However, water is also very corroding and can cause wear on pump parts. Oil is another common type of fluid that is pumped. It is more expensive than water, but it has a much higher viscosity, which means it can be used to pump thicker fluids. However, oil is also more likely to cause wear on pump parts and can be difficult to clean up if it leaks.

Air is the least common type of fluid that is pumped. It is relatively expensive and can be difficult to obtain, but it has a very low viscosity, which means it is easy to pump. Air is also very corrosive and can cause wear on pump parts.

What Are The Main Types Of Energy That Are Used To Power Pumps?

There are many different types of energy sources that can be used to power pumps. The most common type of energy used to power pumps is electricity. Other common types of energy used to power pumps include petrol, diesel, and natural gas.

What Are The Main Factors That Affect Pump Performance?

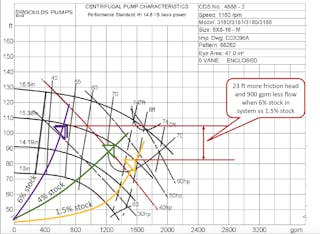

There are a number of factors that affect pump performance, but the three main ones are head, flow rate, and power. The head is the pressure that the pump can generate and is typically measured in meters. The higher the head, the greater the pressure the pump can generate.

Flow rate is the amount of fluid that the pump can move per unit of time and is typically measured in liters per minute (L/min). The higher the flow rate, the greater the volume of fluid the pump can move. Power is the rate at which the pump can do work and is typically measured in watts (W).

The higher the power, the greater the amount of work the pump can do. All three of these factors are important in determining the performance of a pump. If any one of them is too low, the pump will not be able to operate properly.

What Are The Common Problems That Can Occur With Pumps?

Pumps are one of the most important machines in many different industries, and as such, they are often relied upon heavily. However, like all machines, they are not perfect and can sometimes break down or experience problems. Here are some of the most common problems that can occur with pumps: Leaking: One of the most common issues that can occur with pumps is leaking.

This can be caused by a variety of factors, such as worn seals or damaged pump components. Jamming: Another common issue that can occur is jamming. This can be caused by things like foreign objects getting caught in the pump, or dirt and debris buildup.

Motor issues: One of the most critical components of a pump is its motor. If this malfunctions, it can cause the entire pump to fail. Electrical issues: Pumps rely on electricity to function, so any electrical problems can cause major issues.

This can include things like power surges or shorts. Vibration: Excessive vibration is often a sign of a problem with the pump. It can be caused by things like an unbalanced load or misaligned components.

If you notice any of these problems with your pump, it is important to get it checked out by a professional as soon as possible. Ignoring these issues can lead to further damage and expensive repairs.

What Are The Main Maintenance Requirements For Pumps?

Pumps are mechanical devices that move fluids or gases by either displacement or momentum. Pumps operate using different principles and are classified accordingly. The main types of pumps are centrifugal, positive displacement, and special purpose. Pump maintenance is vital to ensure proper and efficient operation.

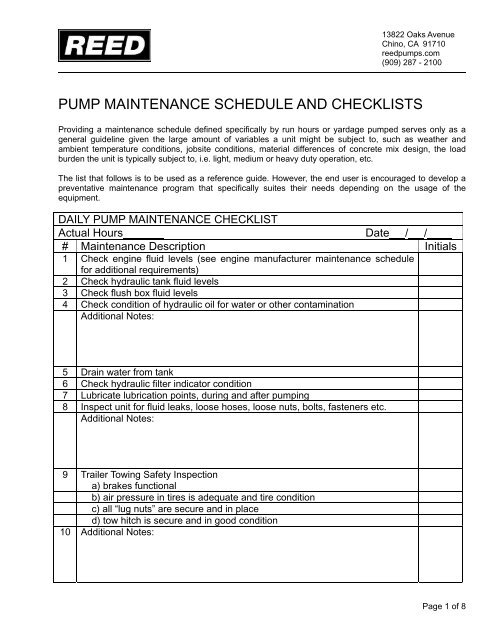

Depending on the type of pump, maintenance requirements will vary. Centrifugal pumps require regular inspection of the impeller and pump housing for wear or damage. The seals and bearings must be checked periodically and replaced as needed. Positive displacement pumps require frequent inspection of the moving parts for wear or damage.

The seals and bearings must be checked periodically and replaced as needed. Special-purpose pumps may have specific maintenance requirements that must be followed to ensure proper operation. Consult the manufacturer’s manual for more information. Generally, all pumps require regular lubrication and servicing to ensure proper and efficient operation.

Consult the manufacturer’s manual for specific maintenance requirements for your pump.

What Are The Main Safety Concerns When Using Pumps?

Pumps are used to move liquids or gases from one place to another, and they are an integral part of many industries. However, pumps can also be dangerous if they are not used properly. Here are some of the main safety concerns to keep in mind when using pumps Make sure that the pump is properly grounded. This will help to prevent electric shock.

Inspect the pump regularly for any signs of wear or tear. If any parts are worn out, replace them before using the pump again. Do not allow anyone to stand near the pump while it is in operation. The moving parts can cause serious injury if someone gets too close.

Keep your hands and clothing away from the inlet and outlet of the pump. The suction can cause clothing or body parts to be drawn into the pump, which can be very dangerous. Never operate a pump without first ensuring that all safety guards are in place. By following these simple safety tips, you can help to prevent accidents and injuries when using pumps.

What Are The Most Efficient Ways To Operate Pumps?

Pumps are essential to a wide range of industries, from agriculture to construction and manufacturing. They come in different shapes and sizes and operate using various mechanisms, but all pumps serve the same purpose: to move fluids from one place to another. There are many different factors to consider when choosing the most efficient way to operate pumps, including the type of pump, the application, the environment, and the specific needs of the user.

Some of the most common types of pumps include centrifugal, positive displacement, and regenerative. Centrifugal pumps are the most common type of pump and are typically used for transferring water or other fluids with low viscosity. Positive displacement pumps are typically used for fluids with higher viscosities, such as oils and fuels, and can also be used for metering applications.

Regenerative pumps are similar to centrifugal pumps but are designed for liquids with very high viscosities, such as molasses and pitch. The efficiency of a pump can also be affected by the way it is operated. For example, a centrifugal pump operating at a lower speed will be more efficient than one operating at a higher speed.

The number of operating hours also affects efficiency, as a pump that is only operated for a short period of time each day will be less efficient than one that is operated for longer periods. Operating a pump at the most efficient speed and for the right duration each day will help to ensure that it operates at its peak performance and lasts for a longer period of time.

What Are The Common Design Mistakes Made When Choosing Pumps?

There are a few common design mistakes made when choosing pumps. The first is not considering the application or system conditions when sizing the pump. The second is not verifying that the pump can actually meet the performance requirements prior to purchase.

The third is not installing the pump properly, which can lead to vibration and noise problems. The fourth is not maintaining the pump properly, which can lead to decreased pump life and increased operating costs.

Conclusion

In conclusion, pumps are devices that transfer fluids by mechanical action. Pumps create a vacuum that sucks in water or other liquids, which are then discharged under pressure.

Leave a Reply